New from WAGNER: PXM powder centers

I ndividually configurable powder centers for a custom-made powder supply.

ndividually configurable powder centers for a custom-made powder supply.

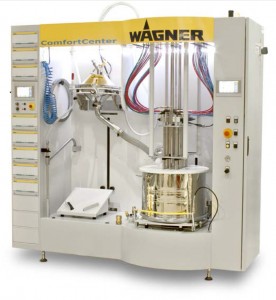

Powder centers form the core of an automatic powder coating system. WAGNER, one of the leading manufacturers, has developed a new generation of its powder centers. The classic open design convinces with its simple structure, accessibility and flexible operation modes compared to other enclosed systems. This way, the new PXM powder center can be adapted to the most diverse customer requirements.

There are selection possibilities for powder addition and preparation. Whether simply out of a stainless steel container or out of the box, whether just with fluidization or shaken using a vibrating table: depending on the requirements, the PXM offers different options in order to achieve optimum powder conditioning. Powder feeding is carried out by injectors with high-performance capacity – in case of delivery from the box, up to 20 injectors are possible, in case of systems with fluid tanks, up to 34 injectors are possible depending on the design. Further options such as an ultrasonic screen can easily be integrated. The fresh powder supply can be conducted manually or automatically, depending on how important interruption-free operation with a high coating quality is.

Further highlights are the good design layout and the clear, intuitively operable 7-inch color display. In addition, improvements have been made which accelerate the color change. On the PXM, the powder is not just blown out of the suction tube interior, but also the outside of the tube is automatically wiped. An intelligent menu guidance accompanies employees through the color change on a display, making the process quicker and safer. Covers for the box and fluid tank complement the functional range. A continuously high coating quality is therefore not only ensured by the easy process control in all coating tasks, but also by a clean working area. Thanks to the modular system, WAGNER PXM offers an ideal solution for each coating requirement.

Further highlights are the good design layout and the clear, intuitively operable 7-inch color display. In addition, improvements have been made which accelerate the color change. On the PXM, the powder is not just blown out of the suction tube interior, but also the outside of the tube is automatically wiped. An intelligent menu guidance accompanies employees through the color change on a display, making the process quicker and safer. Covers for the box and fluid tank complement the functional range. A continuously high coating quality is therefore not only ensured by the easy process control in all coating tasks, but also by a clean working area. Thanks to the modular system, WAGNER PXM offers an ideal solution for each coating requirement.