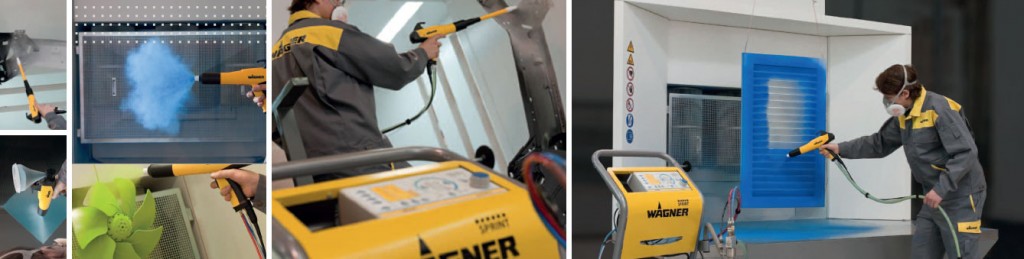

Wagner Manual Powder Coating Systems

Our Wagner manual powder coating systems are perfect for any size of shop or industrial/commercial application use.

The new SPRINT manual system combines a functional and elegant design with comprehensive functionality. All parameters are divided into four functional sections and are entered at the EPG-Sprint X control unit using a central dynamic control dial. Its unique cascade characteristic curve settings together with its Tribo compatibility offer maximum flexibility for each and every powder. In combination with the new manual gun PEM-X1 this manual system delivers excellent coating results.

Weight

Weighing only 490g, the PEM-X1 is a lightweight among powder guns. Despite being light, it maintains its robust design.

Balance

Perfectly balanced to the minutest gram, the PEM-X1 gun is flexible and reduces fatigue.

Ergonomics

The integrated remote control allows for a quick adjustment of the powder amount. Via a double-click on the trigger, swit- ching to another mix recipe is simple and fast.

Nozzles

The new nozzle-concept not only provides a perfect powder cloud, but also an improved finishing quality. The flat spray can easily be adjusted for particular coating requirements, using a sliding ring.

SPECIAL ADVANTAGES

- Compact and always ready-to-use: The set is perfectly suitablefor small quantity production as well as laboratory applications. Independent of ever-changing conditions, the same coating result is obtained.

- System for perfect results: Due to the precise WAGNER regulati- on-technology and the gun-integrated dosing system, small amounts of powder can be applied, while still obtaining incredible results.

- Clear and user friendly: Taking advantage of the simple plugging-system, the powder container is easily attached and handy at the same time.

- Mobile system with convenient case Everything needed for powder-application is provided. Even the smallest piece has its own spot, creating a clear overview.

■ Precision

WAGNER Air Flow Control (AFC) guarantees exact powder control and optimal coating results. A high precision, closed loop regulati- on cycle measures and regulates the air pressure constantly to obtain continuous values.

■ Handling

Easy to locate control elements provides intuitive operation during daily work. The intelligent control unit EPG-Sprint X can easily

be adjusted to any requirements due to numerous adjustment-possi- bilities.

■ Reproducibility

EPG-Sprint X offers direct access to the most used settings and can save up to 50 coating programs. This is how you achieve highest quality and reproducibility.

■ Design

The logical arrangement of the different control parts supports the daily operation. All parameters are always identifiable and guarantee a controlled coating process.

WAGNER manual units –

Efficiency and flexibility in perfect design

The new manual unit combines functionality and extraordinary design. All parameters can easily and quickly be entered in the EPG-Sprint X. By means of a central and dynamic knob, all parameters –grouped into four functional sections- can be set easily. The unique Cascade characteristic line setting and the TRIBO-compatibility offer a high level of flexibility for any powder. In combination with the new manual gun PEM-X1, the manual unit gives perfect coating results. The powder feeding is carried out directly from the original container – optionally out of the 60l stainless steel container.

The South’s leading distributor for Wagner systems and maintenance needs. If you need someone who knows powder coating, then look no further than PSS. We are here to help you in all stages of your business.

For a demo, parts or service please call 615-517-0282.